We schedule automatic packaging production and track the process in real-time through our MES and T+ systems, which maintain vigorous quality control while optimizing costs.

Our workshops’ intelligent management systems effectively reduce personnel redundancy and material waste for shorter, more efficient manufacturing times.

Every ingredient comes with a certificate of composition analysis to show they can withstand long-term usage.

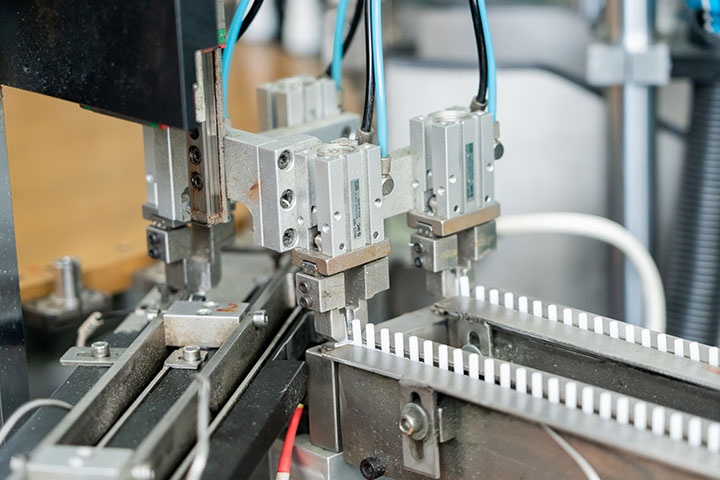

Our factory’s advanced intelligent systems enable fast order dispatching for quicker production.

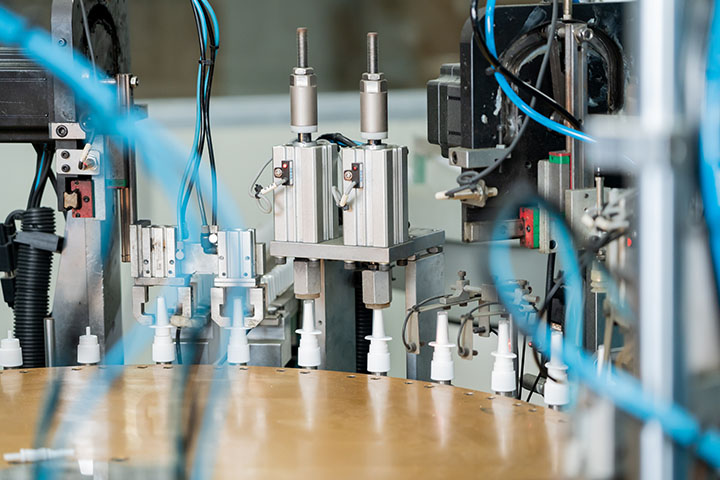

Fully automatic injection molding machines ensured that large volumes of bottles are produced at fast speeds and accuracy.

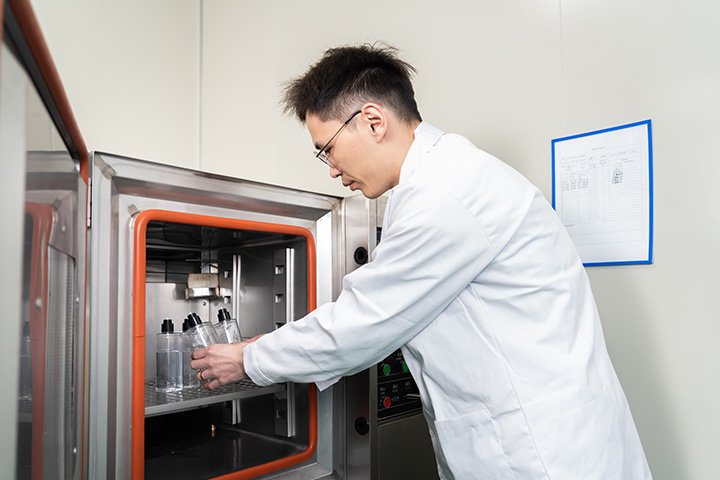

At every step, we conduct quality checks to ensure safety and the reliable performance of our packaging products.

Our careful assembly process helps our products remain undamaged anf leak-proof.

Before shipment, we test our packagings on their vacuum, leak-proof, and temperature control performance.

At KEYNOVO’s production plant, we use vacuum technology to ensure our packaging maintains the freshness of the contents for a long time. We offer diverse vacuum-packed bottle selections to meet the needs of the market.

With highly sophisticated production facilities and timely response from integrated suppliers, KEYNOVO has a capacity of 2 million packages per year, helping you expand your portfilio.

Our vast experience helps us match diverse demands with outstanding production strength by studying your needs carefully to provide stand-out customized personal care and pharmaceutical packaging.

Copyright © 2022, Keynovo. All rights reserved. Powered by MML.

*We respect your confidentiality and all information are protected.

*Please upload only jpg, png, pdf, dxf, dwg files. *Size limit is 10MB.

*We respect your confidentiality and all information are protected.